How to use AGen scan and print labels on car manufacturing and car spare part warehouse?

How to use AGen scan and print labels on car manufacturing and car spare part warehouse?

AGen Scan and Print Labels Software: Streamlining Operations in Automotive Industries

AGen scan and print labels software can be used in car manufacturing and car spare part warehouses to help identify and track products efficiently. Here are 6 steps to use AGen scan and print labels in these settings:

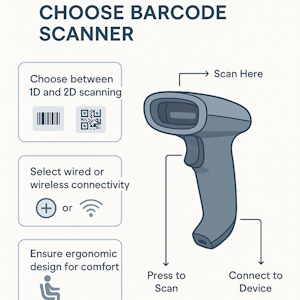

Step 1 - Choose Compatible Hardware

Select a barcode scanner and label printer that are compatible with your inventory management system. Ensure they are easy to use and possess the necessary features for your operational needs. AGen recommends the Zebra TC26, which offers robust connectivity via telco networks.

Step 2 - Configure Inventory System for Barcodes

Set up your inventory management system to generate unique barcodes for each item. These barcodes should encompass vital product information, such as its name, model number, and warehouse location.

Step 3 - Integrate AGen for Item Scanning

Utilize the barcode scanner computer with AGen software installed to scan each item upon arrival in the warehouse or as it's produced on the manufacturing line. This action updates your inventory management system, ensuring accurate product information. AGen is designed for seamless integration with most inventory management systems via text or Excel file connections.

Step 4 - Print Product Labels

Print labels for each item using the label printer. These labels should include the product's barcode and other relevant details like its name, model number, and warehouse location. After scanning the barcode with AGen software, simply click the print button to generate the label directly from your mobile printer.

Step 5 - Apply and Verify Labels

Attach the label securely to the product or its packaging, ensuring it is highly visible and easily scannable. Use the AGen barcode checker to confirm the printed barcode's readability.

Step 6 - Track Products with AGen

Configure AGen to leverage the barcode scanner for tracking each product's movement through the warehouse or along the manufacturing line. This capability assists in monitoring inventory levels, identifying low-stock items, and guaranteeing products are shipped to the correct destinations. Effortlessly check in and check out inventory by simply scanning barcodes with AGen software.

By implementing AGen scan and print labels in car manufacturing and car spare part warehouses, you can significantly increase efficiency, reduce errors, and ensure you always have accurate inventory information. 🚀

By:

pang

| Date:

08 Mar2023