Introduction

Finished goods surface inspection is a quality control process focused on examining the external condition of completed products before they are approved for packaging, storage, or shipment. The inspection aims to identify visible defects such as scratches, dents, cracks, discoloration, stains, or contamination that may affect product functionality, safety, or appearance. This step is especially important in industries where visual quality directly influences customer satisfaction, brand reputation, and regulatory compliance. By conducting thorough surface inspections, manufacturers can ensure products meet defined quality standards and customer specifications, prevent defective goods from reaching the market, reduce returns and rework costs, and support continuous improvement in production processes. Surface inspection may be performed manually by trained inspectors or enhanced through automated vision systems, depending on product complexity and quality requirements.

Feature

Visual Defect Detection – Identifies scratches, dents, cracks, stains, or discoloration

Quality Compliance – Ensures products meet defined quality standards and specifications

Customer Satisfaction – Maintains consistent product appearance and finish

Defect Segregation – Prevents defective goods from reaching packaging or shipment

Manual or Automated Inspection – Supports human inspection and vision-based systems

Traceability Support – Links defects to batches or production lots

Cost Reduction – Reduces rework, returns, and warranty claims

Process Improvement – Provides feedback to improve manufacturing processes

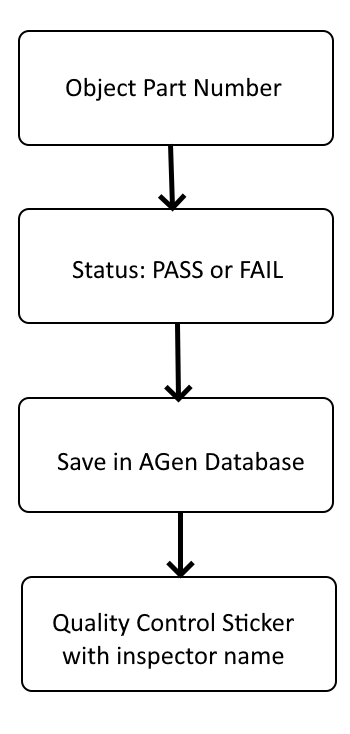

Process Flow

User Interface