Introduction

Finished Goods Quality Control is the final quality assurance process conducted after production is completed and before products are released for storage or delivery. It ensures that finished products fully comply with defined specifications, customer requirements, and regulatory standards. As the last quality checkpoint, this process plays a critical role in preventing defects, protecting brand reputation, and ensuring customer satisfaction.

Features

Final Inspection - Verifies product appearance, dimensions, weight, and functionality.

Specification Compliance - Ensures products meet approved drawings, standards, and customer requirements.

Label & Identification Verification - Confirms correct part numbers, batch numbers, serial numbers, and barcodes.

Packaging Inspection - Checks packaging accuracy, protection, and labeling.

Sampling & Testing - Applies AQL or 100% inspection based on quality risk.

Traceability Control - Records batch and serial information for recall and analysis.

Release Decision - Determines acceptance, rejection, or rework before shipment.

Documentation & Records - Maintains inspection reports and quality evidence for audits.

Process Flow

.png)

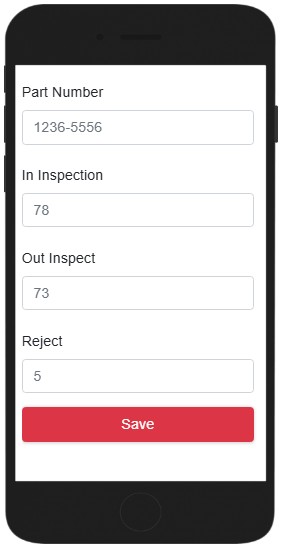

User Interface