Introduction

Finished Goods (FG) Daily Production Counting is the systematic process of recording the quantity of completed, quality-approved products produced each day. It represents the final output of the production process and serves as the official record of what is ready for storage, sales, or delivery to customers. This daily count is typically performed at the end of a shift or production day after all manufacturing and quality inspection activities are completed.

Accurate FG daily production counting is critical for inventory accuracy, production performance monitoring, and business decision-making. It ensures alignment between physical stock and system records, supports reliable customer commitments, and provides essential data for financial reporting and operational analysis.

5 common use counting method include Manual Piece Counting, Standard Pack / Carton Counting, Weighing Method (Weight‑Based Counting), Barcode Scanning Method and Automated Machine Counter

Features

Quality-Approved Output Only - Counts only products that have passed final inspection Excludes Work-In-Progress (WIP) and rejected items

Daily Cut-Off and Traceability - Defined daily or shift-based cut-off time Clear traceability by date, shift, line, or machine

Inventory Integration - Directly updates Finished Goods inventory in ERP or stock records Prevents stock discrepancies and over/under-reporting

Performance Measurement - Supports KPIs such as daily output, yield rate, and scrap rate Enables comparison between planned vs actual production

Operational Accountability - Clear responsibility assigned to production and quality teams Reduces disputes between production, warehouse, and sales

Flexible Data Capture Methods - Can be manual (production sheets), barcode-based, or automated Scalable based on factory size and maturity

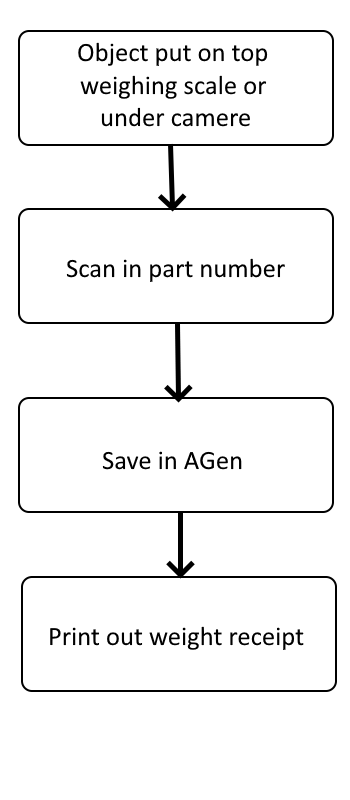

Process Flow User Interface

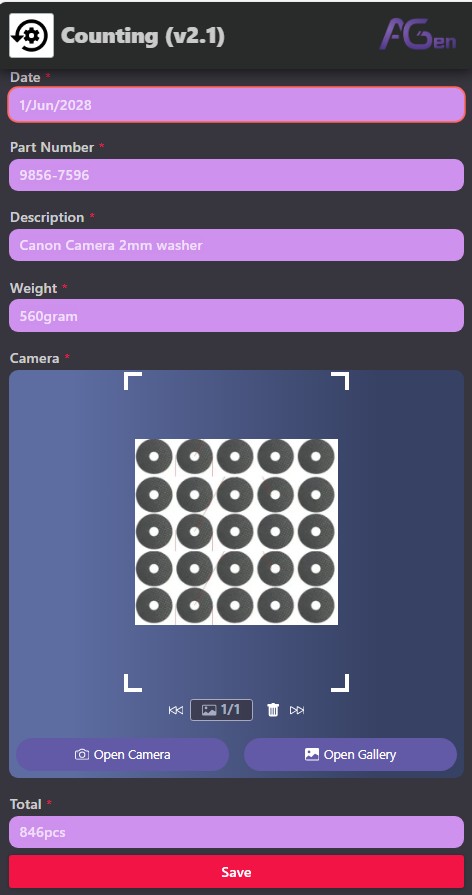

User Interface