Introduction

Laser marking for finished goods is a modern, contact marking technology that uses a focused laser beam to create permanent, high-precision markings on product surfaces. It is widely used in manufacturing to mark serial numbers, batch codes, barcodes, QR codes, logos, and regulatory information. Unlike traditional printing or labeling methods, laser marking does not require inks, chemicals, or physical contact, ensuring clean and durable results without affecting product quality. The markings are highly resistant to wear, heat, and environmental conditions, making laser marking ideal for traceability, brand protection, and compliance across various industries such as electronics, automotive, medical devices, and consumer goods.

Feature

Permanent Marking – Cannot be erased, faded, or removed

High Precision & Clarity – Suitable for small text and complex codes

Non-Contact Process – No damage or deformation to finished products

Maintenance-Free Operation – No consumables like ink or labels

High-Speed Marking – Supports high-volume production lines

Material Versatility – Works on metal, plastic, rubber, glass, and more

Enhanced Traceability – Supports serialization and anti-counterfeiting

Environmentally Friendly – Clean process with no chemical waste

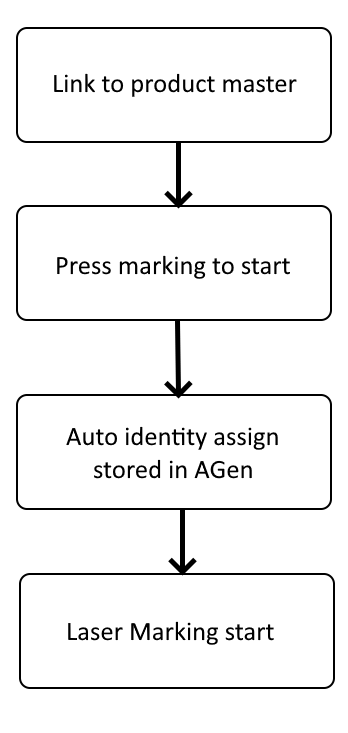

Process flow

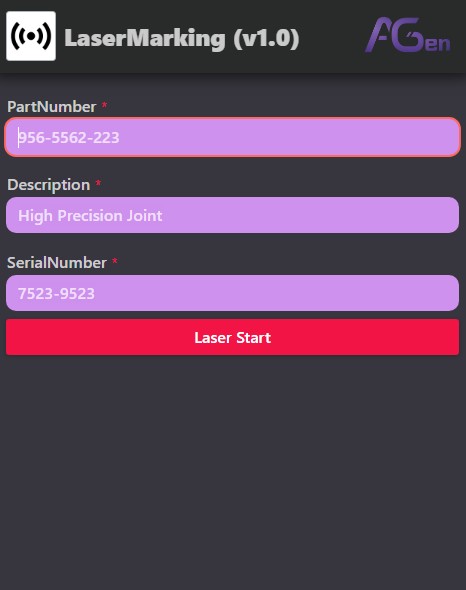

User Interface