Introduction

Raw material return to supplier is a formal procurement and inventory control process where an organization sends raw materials back to the supplier after they have been received. This process is typically initiated when materials are found to be defective, damaged, incorrect, excess, expired, or non‑compliant with agreed specifications. It helps ensure that only suitable materials are used in production, while maintaining accuracy in inventory records and financial accounts.

In manufacturing and supply chain operations, returning raw materials is an important control mechanism to protect product quality, reduce waste, and manage costs effectively. The process is usually governed by company policies, supplier agreements, and quality standards.

Features

Quality Control Driven - Returns are often triggered by quality inspection failures, such as defects, contamination, or specification mismatches.

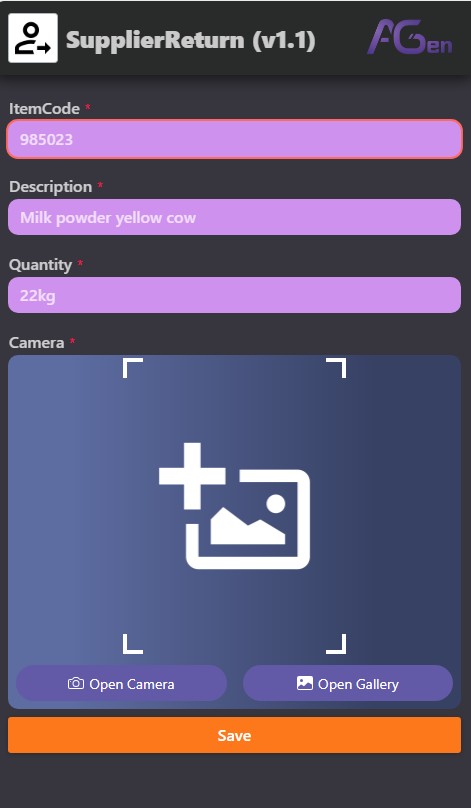

Formal Documentation - The process includes return notes, return material authorizations (RMA), delivery challans, and system transactions to ensure traceability.

Inventory Adjustment - Returned quantities are deducted from stock records to maintain accurate inventory and prevent incorrect material availability.

Financial Impact - Returns may result in a credit note, refund, or replacement, directly affecting procurement costs and accounting records.

Supplier Coordination - Effective communication with suppliers is required to agree on return reasons, logistics, and resolution methods.

Compliance and Audit Trail - Properly managed returns provide an audit trail for internal controls, ISO standards, and regulatory compliance.

Cost and Waste Reduction - Returning unusable materials prevents production disruptions, scrap costs, and downstream quality issues.

.png)