Introduction

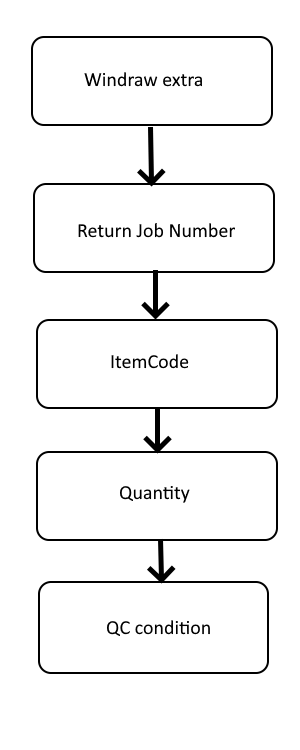

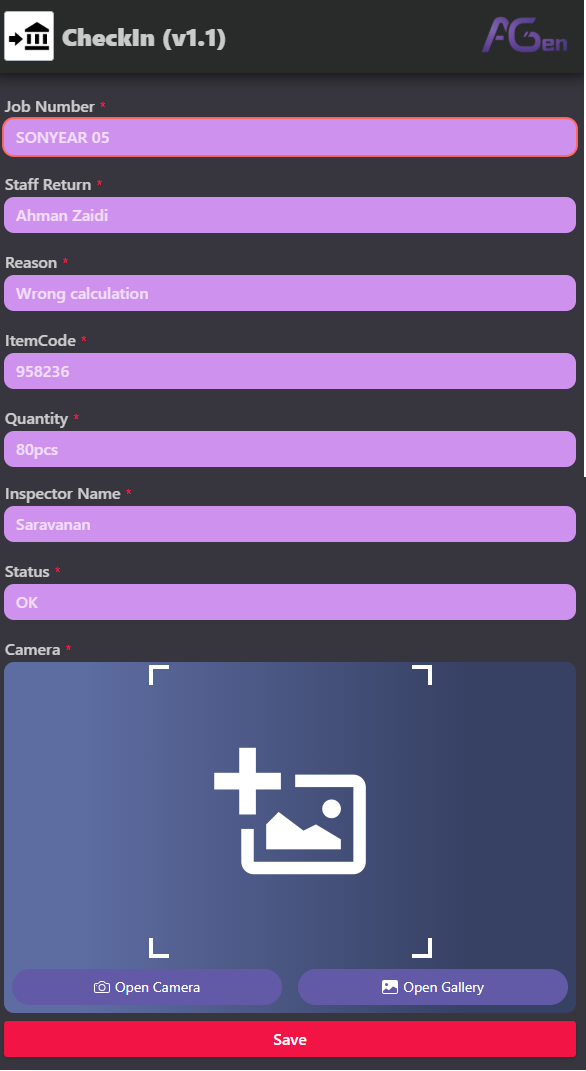

Raw material warehouse check‑in back from production is the formal process of returning unused, excess, or rejected raw materials from the production floor back into the warehouse. This process ensures that inventory records remain accurate, materials are properly accounted for, and reusable materials are made available for future production. It is a critical control point in manufacturing operations to prevent material loss, over‑purchasing, and inventory discrepancies.

Key Features

Material Identification & Segregation - Returned materials are identified by part number, batch/lot number, and production order, and separated from scrap or waste.

Quantity & Condition Verification - Warehouse personnel verify the returned quantity and inspect the material condition to ensure it meets reuse standards.

Documentation & System Update - Return slips or system transactions AGen are completed to update inventory balances accurately.

Quality Control Check (if required) - Certain materials may undergo QA inspection before being approved for reuse.

Proper Storage & Labeling - Approved materials are relabeled if necessary and stored in designated warehouse locations.

Traceability & Audit Compliance - The process maintains traceability for audits, cost control, and production planning.