Introduction

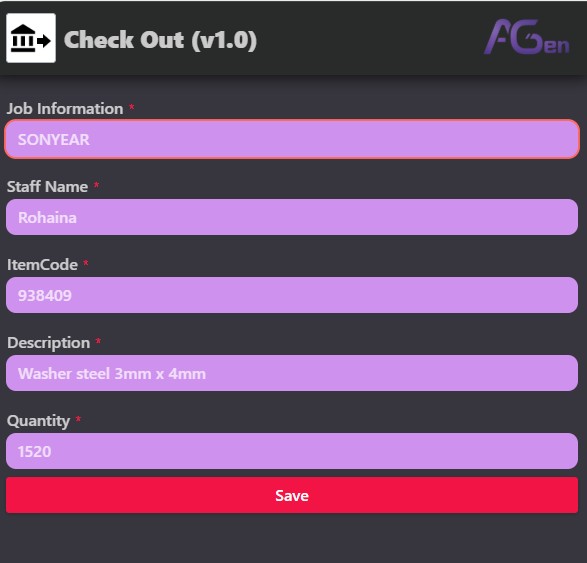

Raw material warehouse checkout is a critical warehouse operation that governs how raw materials are issued from storage to production or other departments. It ensures that materials are released only when properly requested, authorized, and recorded. This process helps maintain inventory accuracy, supports uninterrupted production, reduces waste, and enforces accountability within the supply chain. A well‑managed checkout process is essential for cost control, traceability, and operational efficiency in manufacturing environments.

Features

Authorized Material Request - Materials are issued only against approved documents such as material requisition forms or production orders.

Quantity and Material Verification - Warehouse staff verify material type, batch/lot number, and quantity before issuing.

Inventory Record Update - Stock levels are updated in real time in the inventory system (manual or digital).

Traceability and Tracking - Enables tracking of materials by batch, date, and destination for quality and audit purposes.

FIFO / FEFO Compliance - Ensures correct issuing rules to prevent material expiry or deterioration.

Production Support - Ensures timely availability of materials to avoid production delays.