Introduction

Raw material warehouse put‑away is the process of transferring incoming raw materials from the receiving area into their designated storage locations within a warehouse. This process occurs after materials are received, inspected, and documented. Proper put‑away ensures that raw materials are stored efficiently, safely, and in accordance with production requirements. An effective put‑away process is critical for maintaining accurate inventory, minimizing handling time, and supporting uninterrupted manufacturing operations.

Features

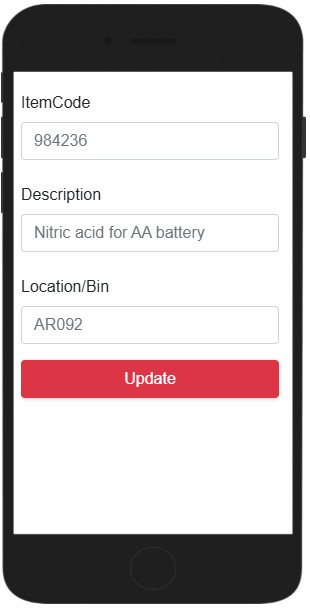

Material Verification - Quantity, quality, batch number, and documentation are checked before storage to ensure accuracy and compliance.

System Recording - Materials are registered in inventory systems (e.g., ERP/WMS) with location, lot, and expiry details for traceability.

Defined Storage Locations - Each material is stored in predefined locations based on size, weight, material type, hazard class, or usage frequency.

Inventory Control Rules - Put‑away follows rules such as FIFO/FEFO to support quality control and prevent material aging or expiry.

Efficient Space Utilization - Optimizes warehouse space by assigning appropriate storage methods like racking, bins, pallets, or bulk storage.

Safety and Compliance - Ensures materials are stored according to safety, environmental, and regulatory requirements.

Production Readiness - Well‑organized put‑away enables fast retrieval of materials, reducing delays in production and operations.