Introduction

AGen raw material warehouse stock take (also known as a physical inventory count) is the process of manually verifying that the physical quantities of materials stored in your warehouse match the records held in your Inventory Management System (IMS) or ERP.

Think of it as a "reality check" for your supply chain. Since raw materials are the starting point of production, any discrepancy here can stall your entire manufacturing line.

Why It Matters

Financial Accuracy: Raw materials represent tied-up capital. Your balance sheet needs to reflect what is actually on the shelves.

Production Continuity: Prevents "stockouts" where a missing ingredient or component halts the factory.

Shrinkage Control: Identifies issues like theft, damage, or supplier short-deliveries.

Waste Management: Spots expired or obsolete materials before they become a total loss.

The Process at a Glance

Preparation: The warehouse "freezes" all movement (no receiving or shipping) to ensure a static environment.

Counting: Staff or external auditors count every item. This can be done via Periodic Stock Take (once or twice a year) or Cycle Counting (counting small portions of inventory daily/weekly).

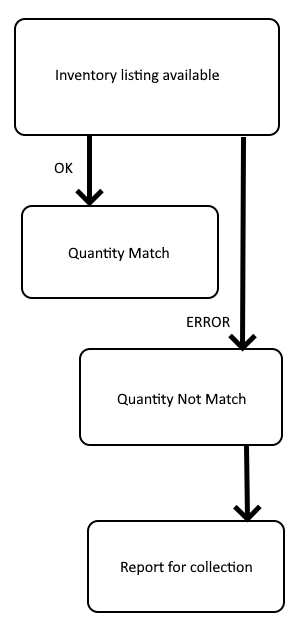

Comparison: The physical count is compared against the system’s "book value."

Reconciliation: If a discrepancy exists, the team investigates the cause. Once resolved, the digital records are updated to match the physical reality.

Key Challenges

Units of Measure: Raw materials are often stored in bulk (liters, kilograms, or meters). Measuring a half-empty 1,000-liter drum is much harder than counting boxes of finished goods.

Work-in-Progress (WIP): Distinguishing between raw materials still in the warehouse and those already moved to the production floor.

Pro Tip: Modern warehouses often use barcode scanners to speed up this process and minimize human error, turning a weekend-long chore into a streamlined task.

.jpg)