Introduction

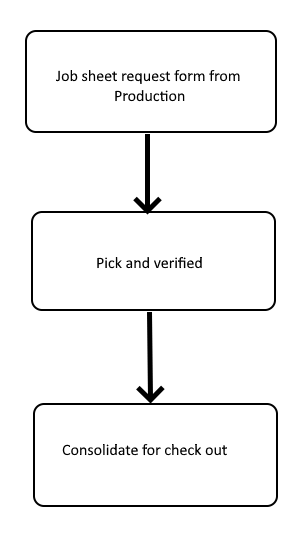

The raw material picking process is the strategic and highly coordinated retrieval of specific quantities of unprocessed goods or components from designated warehouse storage locations to satisfy production work orders, ensuring that the manufacturing line receives the precise inputs required for assembly at exactly the right time to maintain operational flow while simultaneously updating inventory levels to reflect real-time stock consumption.

Features of the Process

Directed Movement: Utilizing AGen, pickers are guided through the most efficient routes (such as wave or zone picking) to minimize travel time and physical fatigue.

Verification Protocols: Features "double-check" mechanisms—such as barcode scanning or Pick-to-Light systems—to ensure the part number and quantity picked match the bill of materials exactly.

FIFO/FEFO Management: Logic-driven picking ensures that the oldest stock (First-In, First-Out) or materials closest to expiration (First-Expired, First-Out) are used first to prevent waste and obsolescence.

Inventory Synchronization: Every pick action triggers an immediate digital deduction from the warehouse stock, which can automatically initiate "reorder point" alerts for procurement teams.

Kitting Capabilities: The process often involves "kitting," where multiple raw components are grouped together into a single production-ready package to streamline the transition from storage to the factory floor.

.jpg)