Introduction

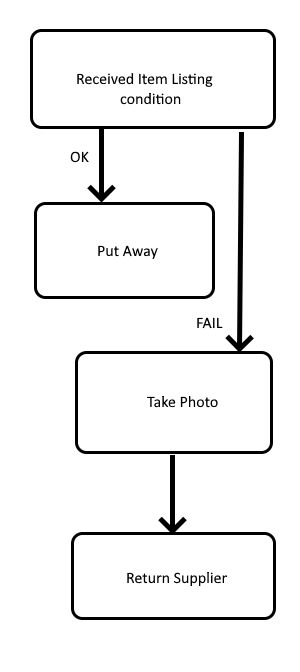

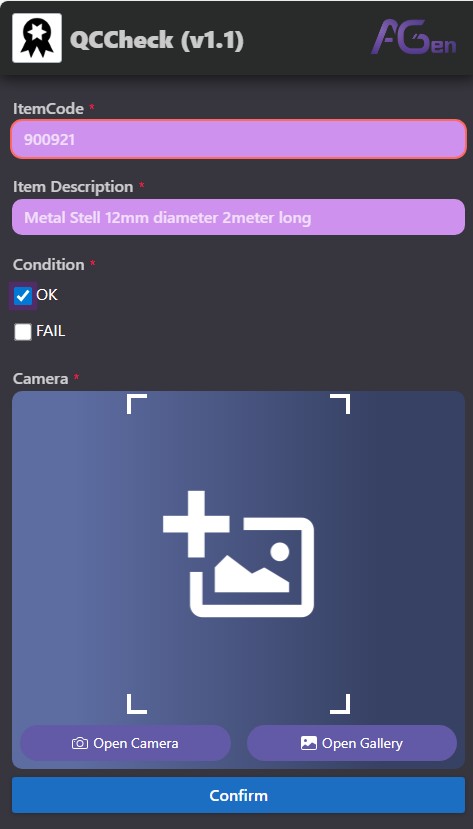

Raw material warehouse quality control (QC) inspection is critical because it ensures that incoming materials meet specified quality, safety, and compliance standards before they enter production, directly preventing defects, production delays, safety incidents, and costly rework caused by substandard or incorrect materials. By detecting issues such as damage, contamination, incorrect specifications, or expired materials at the point of receipt, QC inspection protects product integrity, supports regulatory compliance, and stabilizes production quality. Using software to record inspection results further strengthens this process by standardizing inspection checklists, enabling real-time data capture (often via mobile devices), attaching photos or certificates, and providing automatic pass/fail decisions with full traceability by batch, supplier, and date. This digital record allows faster root-cause analysis, trend monitoring of supplier quality, audit readiness, and seamless integration with inventory or ERP systems—transforming QC from a manual gatekeeping task into a data-driven quality assurance and continuous improvement tool.

Data captured:

Inspection result (Pass / Fail / Conditional)

Inspection date & inspector

Test results (dimension, hardness, grade, etc.)

Rejection reason (if any)

System action:

❌ Failed → move to Quarantine location

✅ Passed → released to Available stock